Wygodne ustawienia nawigacji

Poniższe informacje zapewnią ci łatwy przegląd tego, co stanie się z Twoimi danymi osobowymi podczas odwiedzania tej witryny.

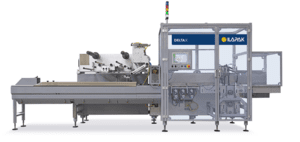

ILAPAK has expanded its Delta series of modular flow wrappers with the launch of a dedicated bakery industry model. The Delta X takes ILAPAK’s popular MAP flow wrapping platform to a new performance level on bakery applications, thanks to a new solid and robust frame, an efficiency-enhancing redesign of the transversal sealing system, ergonomic and improved film reel mounting and open frame style guards, together with an overall footprint reduction.

The launch of the Delta X - on display for the first time ever at All4pack 2018, Stand 6G 082- follows hot on the heels of the introduction earlier this year of the Carrera 5000 – a dedicated bakery industry flow wrapper for non-MAP applications – and underlines ILAPAK’s commitment to sector-specific R&D.

“Bakery is a very important industry for us, representing approximately 50% of our customer base,” says Christian Ballabio, project engineer at ILAPAK. “We have thousands of Delta flow wrappers installed in the field globally, and feedback from our customers is that they want greater efficiency without any compromise in sealing performance. This is the brief our engineers have been working to, whilst balancing the industry’s requirements for ease of access, space efficiency and simple operation.”

He continues: “We will be showing the Delta X at the All4Pack exhibition in November and anticipate lots of interest from producers looking for a reliable and efficient solution for packaging bakery items such as rolls, pizza, tortillas, croissants, pies, muffins, cookies and snacks in a modified atmosphere.”

Using the high-spec Delta 6000 as the starting point, ILAPAK’s engineers have removed some of the features that aren’t needed by bakery users, and redesigned the flow wrapper for faster operation, improved sealing performances and easier operability.

Capable of creating high integrity hermetic seals at speeds of up to 200ppm and accommodating film thicknesses of up to 200 micron, the new Delta X boasts the highest speeds and the best seal performance in the Delta series. ILAPAK has achieved this by re-engineering the transversal sealing system, the machine frame and the film reel mounting operation.

Heavy duty shafts, bigger motors and gearboxes and helical bevel gears make for a more robust transversal sealing system design, allowing greater and more consistent seal-jaw pressure to be applied, whilst long dwell sealing jaws ensure maximum hermetic seal integrity. For the longitudinal sealing system, the successful concept from the Delta 6000 has been maintained. This deploys four sets of heated rollers with parallel opening to increase the sealing distance.

A radical re-engineering of the machine frame has produced a robust tubular frame that weighs 20% more and has a lower centre of gravity for maximum stability and minimum vibration at high speeds. But although the frame weight has increased, the overall in-line footprint has been reduced, making the Delta X a more compact solution for space-constrained factories.

ILAPAK has also improved the ergonomics of the film reel mounting operation, creating 20% more space for reel loading, reducing the number of rollers, film splicing and changeovers and allowing these tasks to be carried out closer to floor level. In addition, rapid film reel change is facilitated by a pneumatic locking device on the shaft. The splicing operation is more ergonomic too, as the splicing table on the Delta X is flat rather than inclined.

The Delta X is operated via a large 12.5” HMI (the other machines in the Delta range come with a 10” screen as standard) and instead of on-board safety guarding, full-length double doors allow full visibility of machine parts and easy access for maintenance and cleaning.

This new flow wrapper is available in two configurations: a narrow model for products of up to 200mm in width and a wider model for products of up to 450mm in width, in either stainless steel or painted executions. The Delta X is geared towards conventional pillow bag production, but, like the other machines in the Delta series, is modular in its design, which gives users the option of customising their machines with modules for gusseting, labelling and application of clips and reclosable zippers.

Want to see the Delta X in action? Come visit us at All4Pack 2018, Paris, 26-29 November 2018, Stand 6G 082

Wypełnij ten formularz, aby być zawsze na bieżąco z rozwiązaniami Ilapak